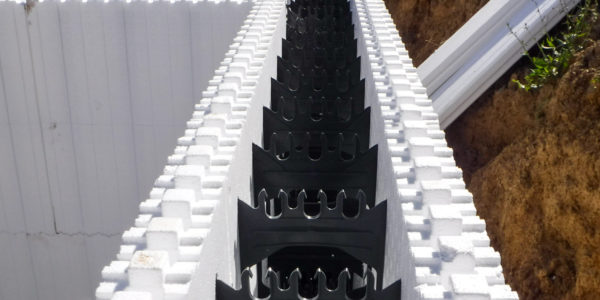

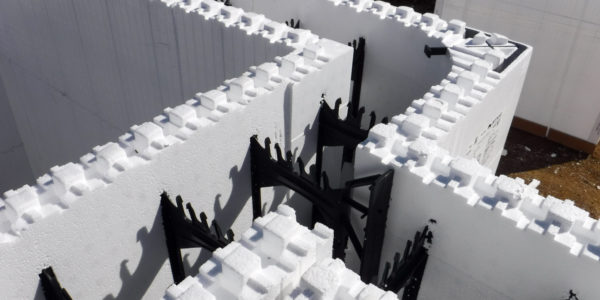

This #TechTuesday we are presenting another great product that we believe in! Insulated Concrete Forms or simply ICFs are hollow, lightweight forms manufactured using high density expanded polystyrene (EPS) panels that are connected by 100 percent recycled polypropylene webs, making the blocks 60 percent recycled material by total weight.

ICFs offer the strongest, healthiest, low maintenance and cost efficient developments to date! It is energy efficient, safe and resilient.

Michael Sebright, president of Evolve Build:

“I met Manfred Knobel, ICFs installer, during the World of Concrete 2006 in Las Vegas. Manfred and I had a conversation about the solutions for building going forward – it was a start of Energy Reconsidered. Now we use ICFs on 10+ projects because it allows us to build fast and strong. ICFs are also attractive from the design point of view as design possibilities are limitless. The reason we use it is simple – it is the best product on the market because of speed, cost and sustainability.”

ICFs offer a “5 in 1” solution that provides structural strength, insulation, vapor barrier, sound barrier and attachments for sheet rock and exterior finishes in one easy step. ICFs produce high performance buildings that are designed and constructed to minimize maintenance and repair, offer low energy consumption reducing operating costs and has the ability to continue functioning in adverse situations.

Benefits of an ICF:

- 30-70% savings in energy consumption and costs

- Tornado, hurricane and earthquake resistant

- 75% reduction in outside air infiltration (less dust and allergens)

- Five times quieter than a wood-frame home

- Building with ICFs saves at least 10 trees per home

- ICFs can be used to build virtually any home plan, using any finish – brick, stucco, siding, and more.

Paul Camozzi, Director of Commercial Development at Amvic:

“Using insulated concrete forms is quickly becoming one of the healthiest and fastest ways to create the tighter continuous Insulated envelops necessary for high-efficiency homes. ICFs are durable, resilient and innovative. They offer protection from fires, earthquakes, severe storms and flooding. Government led public/private programs and National Building Codes are supporting and recognizing disaster resilient building design and continuous thermal insulation which have changed from traditional construction methodologies to providing green buildings with measurable results. ICF construction contributes strongly to building safer communities while achieving sustainable construction and a healthier way of life.”

ICF construction results in durable, resilient structures that are environmentally friendly and resource-efficient throughout the building’s life-cycle; from the planning, construction, operation, maintenance, renovation and demolition phase. Green building ICFs construction contributes strongly to building safer communities through sustainable construction and providing a healthier way of life for years to come.

Some might argue that an expandable polystyrene (EPS) barrier filled with concrete is not necessarily eco-friendly, but the true environmental friendliness of insulated concrete forms lies in the big picture of sustainability and detachment from utilizing more natural resources.

Building a new home with insulated concrete forms is environmentally responsible. The cement in concrete is made of limestone which is the most abundant mineral on Earth and EPS produces only 1% waste in our landfills. Compare that with all the acreage of timber destroyed in logging activities to produce construction lumber and ICFs already have an early advantage.

The real environmental impact is achieved over years and years of home ownership. Take for example:

- At least 22 trees are required to be harvested for the lumber in a stick frame home.[1]

- ICF forms reduce energy usage which helps preserve natural resources.[2]

- ICFs are more efficient in heating and cooling and can reduce energy consumption. Saving up to 40% in energy costs.[3]

- There is less construction waste associated with ICF forms compared to stick frame building. ICFs deliver 1% – NET 0% waste by the end of the project compared to upwards of 15%.[4]

- EPS is comprised of 95% air and displays a .[5] ICF foam panels are made of 2% plastic derived from a petroleum by-product (usually harvested from already existing petroleum waste) with a 1% noncombustible component. Making the foam panels 100% recyclable for multiple manufactured products. There is no limit to the amount of times EPS foam can be repurposed into another product.[6]

Although only accounting for 2% or less of the EPS panels in ICFs, flame retardants and fossil fuels are indeed being used to produce the expandable polystyrene foam of ICFs. This is why it is imperative to minimize construction waste and recycle the EPS waste from jobsites to repurpose this carbon material into other products and resources. Although flame retardants and non-organic materials aren’t the best eco-friendly elements out there, they assist in making sure an ICF structure stands up to natural disasters and is free of rot, mold, insects and pests. This ensures a longer lasting, stronger and more resilient, maintenance free home or building.

Eddy Paiz, Piaz Construction:

“It has been a beautiful experience installing the ICF walls at Kingsley Court. We were impressed how easy and fast it was. Now, my team and I are looking forward to do more projects with ICFs in the future”

ICF forms have a lifespan of 75+ years, meaning their environmental damage during manufacturing prorated over that period is miniscule. It can still be argued that there are very few, if any, “perfect” green construction materials as of yet. As it stands now though, insulated concrete forms are at the top of that list. The reduction in energy consumption over multiple decades provides the best option for green construction today. ICFs will continue to push the limits of current standards and will strive to be the greenest and strongest method of building in the years ahead.