Happy #TechTuesday! Today we are covering a very complex system that you probably never heard of before. The reason being is that it is not available on the US market.

Patented in Europe, ®ISOMAX is a fully integrated building system that collects solar heat energy and stores the heat in the earth just under the building.

“Nowadays, about 46 % of all energy raw materials such as crude oil, natural gas and coal are being used for air-conditioning purposes, i.e. for heating and cooling of buildings – an unjustifiable luxury considering the fact that both ecologically friendly and economically useful alternatives are available. Despite a great variety of activities regarding the utilization of renewable energies the expenditure of primary energy for the manufacture of such systems and facilities as well as the initial costs for photo-voltaic installations, solar collectors or heat pumps are definitely still too high as compared with the energy savings achievable.” – Edmond Krecké, Inventor & Scientist from Luxembourg, Europe

HOW IT WORKS

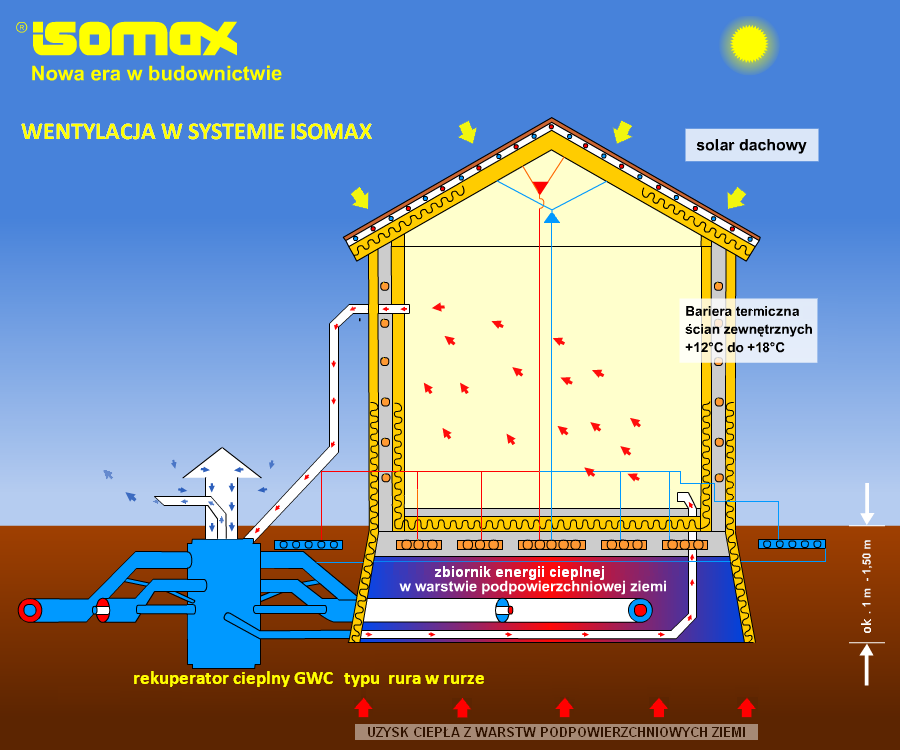

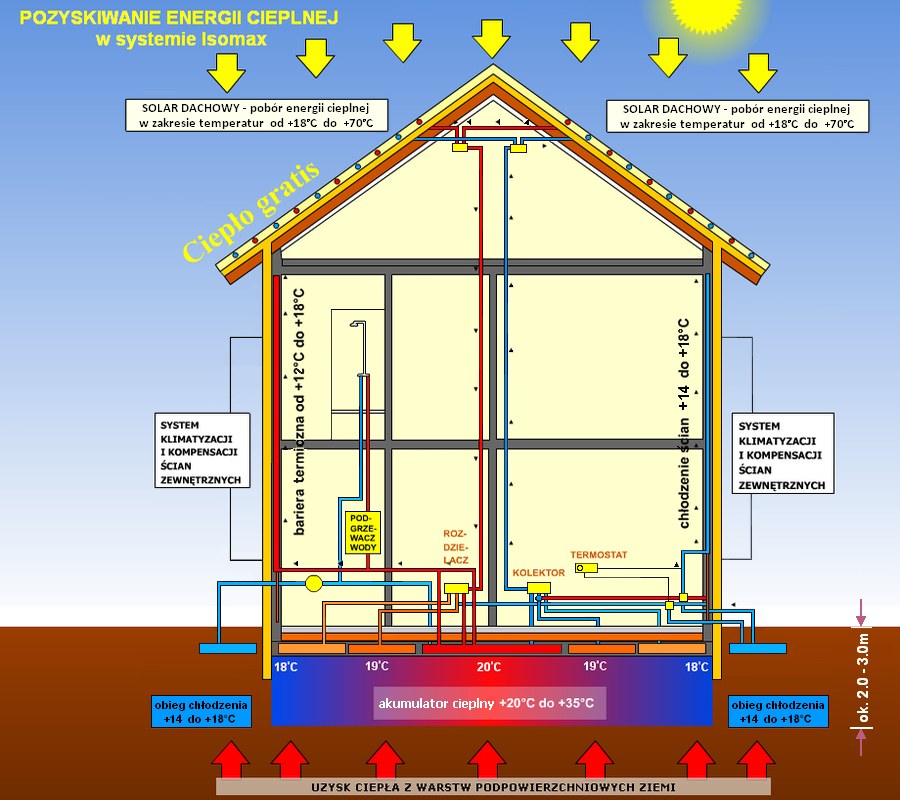

The system uses circulating fluid to transfer heat between the earth storage and the building envelope. The process allows the entire envelope of the building to take advantage of the collected energy by running the fluid, warmed or cooled, to move heat into or out of the insulated concrete wall and the roof.

WHY USE IT

The ®ISOMAX Building Technology as a whole furthers the notion of living building standards by integrating the building shell and conditioning components into an active system that can store or collect energy in response to the exterior weather conditions and the internal comfort levels of the occupants. In the European market, this type of building construction has delivered an average heating load of approximately 24 kWh / (m2 /a) which is just above those of a passive house standards that have set the most restrictive benchmarks for the heating and cooling load of a structure not to exceed 15 kWh/(m2 /a).

The ®ISOMAX building system relies on two ideas that are different than those currently being used in a high performance buildings or passive house standards. The first concept is the transformation of the exterior wall from a passive thermal resistance to one that can actively participate in the temperature control of the interior. This is accomplished by the heat transfer fluid which moves heat into and out of the walls and roof. The roof captures the naturally occurring solar heat energy for storage in the earth. The second concept is to utilize the earth as a thermal medium to provide cooling, heating, and storage to allow for temperature regulation of the building. The structure interacts with the earth-stored energy, allowing it to be stored and recalled as needed over time.

WHO INVENTED IT

The ISOMAX® building system is the brain child of Graduated Engineer, Physicist Edmond D. KRECKÉ, Inventor & Scientist from Luxembourg, Europe. He has been involved in the development and adoption of the building system in more than 50 countries in the world. He is the advisor to numerous national governments on the building system after having an amazing record of expertise in construction of sustainable and efficient passive housing. Mr. Krecke is the President of the Presidential Council – Berlin / Monaco / Zurich / Washington and has also been nominated by the Executive Board of the Association of German Engineers for the Nobel Prize for Physics.

FLEXIBILITY

The ISOMAX® system combines the components of building construction and building services equipment to provide a future-oriented, resource-saving and therefore sustainable, environmentally friendly system design. Noteworthy is its versatility and related applicability both in the design of new buildings, as well as in the general modernization of old buildings. The ISOMAX® system promotes and allows each individual building design, both architectural and constructive planning approach, under their respective state of the art.

The ISOMAX® construction technology provides self-sufficient building technology. The residents will have a cost-neutral building with a health-promoting and physiologically reasonable comfort level.

Special characteristics ISOMAX® system:

- Optimal insulation both sound & temperature barriers

- Speed of construction using both precast and partially pre-cast systems.

- Cost comparable to convention system with added advantage of thermal comfort

- Solar absorber lines between roof and roof insulation possible

- Extension of building system technology with photovoltaic technology

- Pleasing and better aesthetic appearance

ASK US HOW WE CAN HELP YOU CHANGE THE WAY YOU BUILD!

LEARN MORE

http://www.isomax-terrasol.eu/fileadmin/_migrated/content_uploads/ISOMAX-TERRA-SOL-engl_01.pdf

http://www.isomax-terrasol.eu/home.html

http://www.phrc.psu.edu/assets/docs/Publications/2013RBDCCPapers/Sebright-2013-RBDCC.pdf

http://www.isomax-terrasol.eu/fileadmin/_migrated/content_uploads/ISOMAX-building_for_KASHMIR.pdf